Radiographic Testing

Radiographic Non Destructive Testing is used to inspect materials and components for any defects not apparent on the surface

Have Questions About

Get in Touch: Email or Call Code Inspection and Testing Co. Today! (337) 504-5904

Radiograph Inspection

High Quality Inspections Done by Professionals

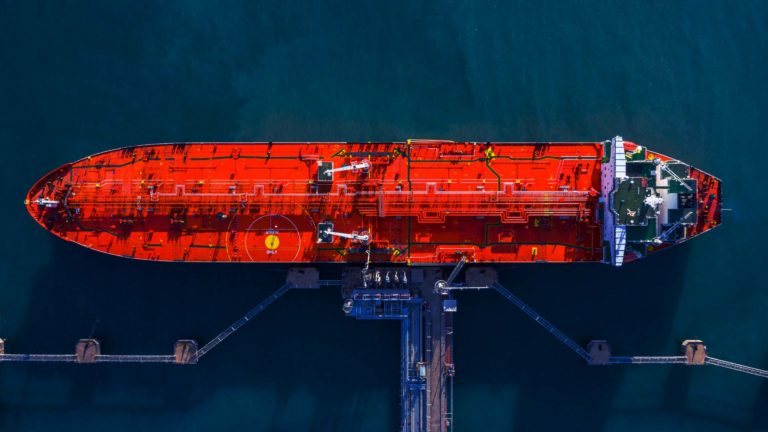

Radiographic Inspection is quickly becoming one of the top methods of Nondestructive testing on the market today. Code Inspection and Testing Co. provides this inspection service to a variety of industries, including but not limited to Aerospace, Energy, and Power Generation Sectors.

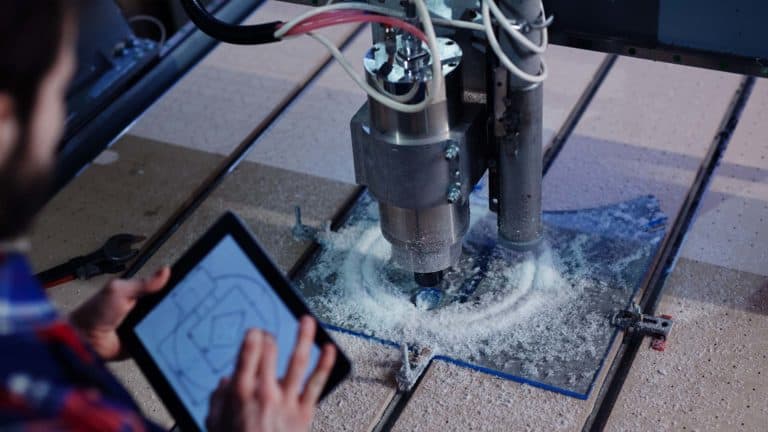

Radiographic Testing uses gamma or X-rays to scan and penetrate surfaces in order to detect flaws in weld quality, castings, structures, and composites. Favored by fabricating and casting industries for quality control, for its ability to reveal faults such as porosity, inclusions, and cracks.

Code Inspection and Testing Co. employs certified inspectors familiar with radiographic inspection procedures. Inspectors will use an isotope or an x-ray tube to create an image. Volumetric inspection detects defects which are not open to the surface, and which may not otherwise be detectable.

Commonly Inspected Components

- Pressure Vessels

- Boilers

- Casting

- Aircraft Structures

- Welds and Weld Overlays

Proudly Serving our Customers for over ten years

Get More With Code Inspection and Testing Co. Services