Infrared Thermal Inspection

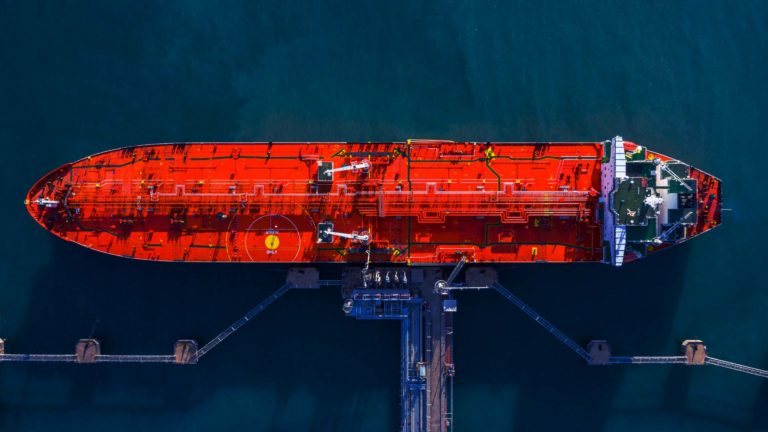

Widely used in oil and gas industries for conditioning monitoring and damage preventative

Have Questions About

Get in Touch: Email or Call Code Inspection and Testing Co. Today! (337) 504-5904

Infrared Technology (IRT)

A form of NDT that is directly related to changes in temperature

Infrared Thermal Inspection holds several advantages over other inspection methods due to the fact that it does not require contact with the material or equipment being monitored. Infrared Thermal Inspection is a form of nondestructive testing that measure the temperature variances as heat flows through, in , or out of a component. This method relies heavily on heat output as a component changes temperature, the amount of radiation emitted changes. Because this form of radiation is invisible to the naked eye, components have to be reviewed using infrared cameras.

These cameras produce images that map out the levels of heat in the surrounding area. Areas of heat will be displayed either red or yellow while cooler areas are displayed in blues and purple. These images or reviewed by a certified inspector to detect any hot spots where equipment may weaken or fail and discuss a course of action if required.

There are five methods of Infrared Thermal Inspection. Each method has different advantageous and test different types of heat emission. Passive Thermography, Active Thermography, Vibrothermography, and Lock-In Thermography.

Infrared Thermal Testing is able to detects signs of:

- Corrosion Damage

- Voids

- Inclusions

- Gas Leaks

- Areas of Moisture

Proudly Serving our Customers for over ten years

Get More With Code Inspection and Testing Co. Services